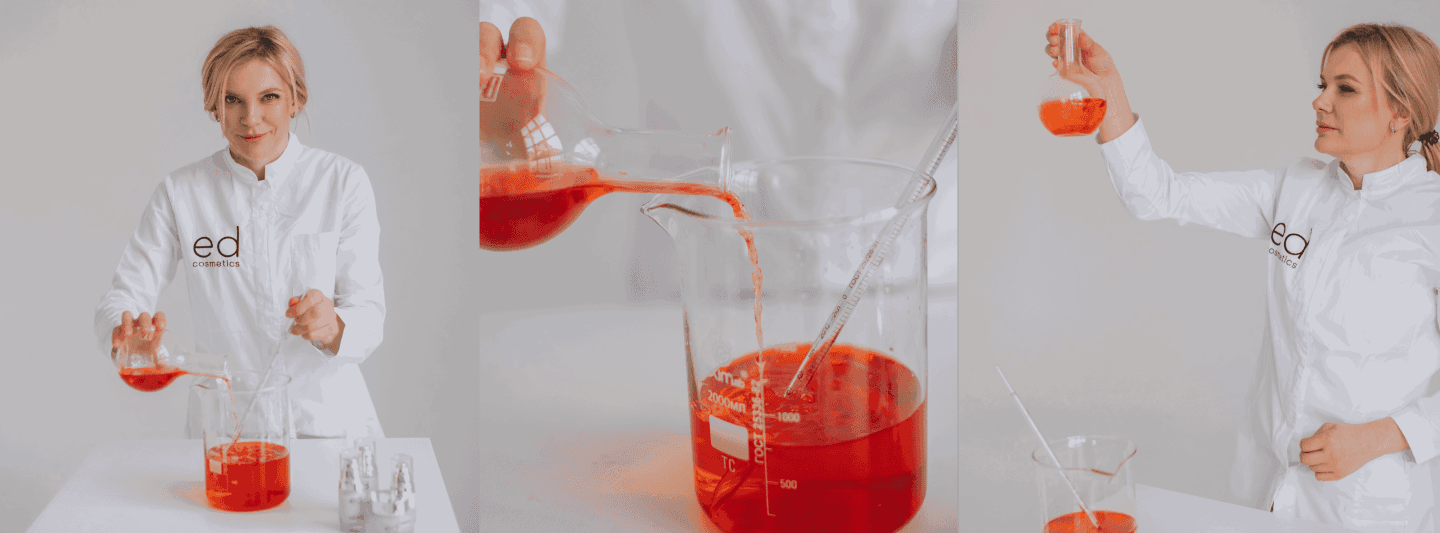

Advantages of Local Manufacturing: Speed, Control, Adaptability

In 2024, over 18,000 new cosmetic brands entered the market, and nearly 60% of them used the services of OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) companies. This data indicates a global trend toward outsourcing production in the cosmetics industry. Brands no longer build their own factories, hire technologists, or develop formulas independently. Instead, they turn to contract manufacturers to quickly create a product, test it, and bring it to market with minimal risks. This is an excellent option for startups, niche brands, and private lines.

When choosing where to create your cosmetic product, it's worth considering local production. It’s faster, more flexible, better controlled, and avoids complex logistics and extra costs. So, what are the other advantages of local manufacturing, and what should brands pay attention to?

Faster Time-to-Market

In the beauty industry, time is as valuable a resource as budget. That's why the ability to launch new products quickly is one of the key advantages of local manufacturing.

Working with a local partner, a brand avoids spending months on logistics, importing samples, or customs clearance. Everything from formula testing to packaging approval happens on-site, in close collaboration with technologists and designers. This allows a product to launch in 2–4 months on average, while working with foreign manufacturers can take 6–12 months or more.

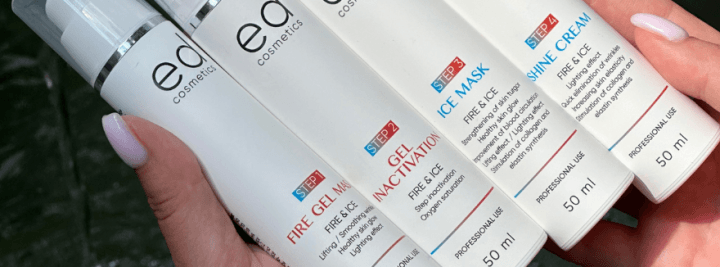

Additionally, ED Cosmetics offers ready-made base formulas (ODM) for those who want to enter the market as quickly as possible, as well as the opportunity to create a custom formula (OEM) without time wasted on bureaucracy or complex logistics.

Stages of Launching a Private Label Product:

- Request & Consultation

- Familiarization with the manufacturer’s capabilities

- Discussing needs: product type, audience, positioning

- Choosing the format: ready-made formula (ODM) or custom development (OEM)

- Technical Brief

- Submitting a brief: text, concept, skin type, expected effect

- Coordinating packaging, volume, texture, scent

- Determining batch volume

- Formula Selection or Development

- Manufacturer proposes ready-made options or develops from scratch

- Samples sent for testing

- Adjustments possible (color, scent, consistency, etc.)

- Documentation

- Product certification according to legal requirements

- Providing technical passport, ingredient list, MSDS, etc.

- Production

- Purchasing raw materials and packaging

- Batch manufacturing

- Quality control and laboratory testing (internal and external)

- Filling and Labeling

- Bottling, label or logo application

- Packaging

- Delivery

- Finished products delivered to the client

- Option for storage at the manufacturer’s warehouse

ED Cosmetics supports clients at every stage — from idea to the launch of a finished line.

Enhanced Quality Control

Control over all stages of production is key to consistent results. Local facilities enable the implementation of:

- Automated lines (filling, packaging)

- IoT systems for monitoring temperature and humidity

- Defect control systems

For instance, implementing Smart-factory models within cosmetic enterprises reduces defective batches by 27.6%, increases prototype production speed by 7%, and cuts overall costs by 29%.

Adaptability to Change

A local manufacturer is more flexible: formulas, packaging, and volumes can be quickly adjusted to meet demand. Proximity to the market allows for immediate response, minimizing logistics delays — crucial during seasonal promotions. Regional supply chains reduce transit time and customs risks, while enabling a high level of responsiveness to customer needs.

This is exemplified by ED Cosmetics’ experience: once, a new cream developed a yellowish tint that didn’t match the chosen transparent packaging. Thanks to local production, the team quickly resolved the issue without halting processes or incurring additional losses. If the manufacturer had been abroad, this could have resulted in serious delays.

Local Expertise

Domestic production greatly simplifies compliance with national and EU legislation, including standards such as REACH, GMP, ISO, and regulations on cosmetic safety assessments.

Compared to importing finished products, local production helps avoid complicated customs procedures, translating technical documentation, and adapting formulations and packaging to market requirements. This not only reduces costs but also significantly accelerates product launch.

The ED Cosmetics team is experienced with current EU, Ukrainian, and other international regulations, ensuring full certification support — from drafting technical documentation to preparing dossiers and samples for official agencies. This is especially valuable for brands launching their first product or entering new markets. Proper documentation is not just a formality — it’s a guarantee of safety, trust, and compliance.

Local manufacturing is not just a trend — it’s a strategic advantage. Fast launch, full control, adaptability, and simplified regulatory compliance allow brands to enter the market efficiently, with quality and minimal overhead.

Working with ED Cosmetics means getting not just a manufacturer but a partner supporting every step — from idea to finished product. In a world where time and flexibility are critical, a local approach is an advantage that works in your favor.